IN THIS SECTION

Projects

102 Rivonia Road + –

Project start: June 2012

Project status: Current

The building is comprised of three elements, an eight storey building with atrium space transected by stair and bridge links, a 14 storey office tower connected by a four story high bridge and a two storey podium on which the building rests. The podium forms part of the eight storey parking basement.

The built footprint will be 98 800 square metres and by completion the project will have used approximately 39 000 cubic metres of concrete, two million bricks, 6 000 tonnes of rebar and 98 000 square metres of formwork.

The short construction time has required the team to work to a fast-track programme. At peak, Murray & Roberts Buildings will deploy more than 1 000 employees on site to meet the construction deadline.

The development is guided by an environmental management plan and once complete the building will have a 4-star green rating.

Alusaf Aluminium Smelter + –

BRIEF FACTS:

Client: Alusaf

Location: Richards Bay

Commodity: Aluminium

Overall project value: R7,2 billion

Completion: 1996

Client: Alusaf

Location: Richards Bay

Commodity: Aluminium

Overall project value: R7,2 billion

Completion: 1996

Alusaf's Hillside Aluminium Smelter is the global benchmark for similar projects, with its success leading to the Mozal Smelter in Mozambique. The new smelter was one of the largest private enterprise projects under construction in the world at the time.

Sixteen Murray & Roberts companies from every operating group were involved in various contracts for the project.

Construction of the smelter provided a welcome boost to the local economy. Over 85% of the construction contracts were awarded to South African firms with more than 30 000 jobs created. The overall South African content, including proprietary process equipment, exceeded 73% of the capital cost.

The first aluminium metal was transferred to the casthouse on 25 June 1995 - five months ahead of schedule and almost R1 billion under budget.

Murray & Roberts was proud to have been involved with the Alusaf Hillside Smelter project.

ACHIEVEMENTS:

- Completed R1.2 billion under budget and five months ahead of schedule

- Received a Fulton Award in the civil engineering category

- This project showed that South African concrete and engineering expertise for such a major project could measure up to the best on a global scale

Angel Platform Topside Floatover + –

BRIEF FACTS:

Location: North West Shelf, Western Australia

Client: Woodside Energy Ltd

Contract Value: A$45,000,000

Contract period: November 2005 - June 2008

Safety Statistics: Manhours: 227,962 | LTIFR: 4.38

Location: North West Shelf, Western Australia

Client: Woodside Energy Ltd

Contract Value: A$45,000,000

Contract period: November 2005 - June 2008

Safety Statistics: Manhours: 227,962 | LTIFR: 4.38

The Clough Aker Joint Venture (CAJV) was awarded a transport and installation contract for the topside platform required on the Angel Gas Field Development, off Karratha on the North West Shelf, Western Australia. The Angel Field is located in 80 metres of water, approximately 49 kilometres east of the venture’s North Rankin A and Goodwyn A platforms.

The engineering, construction and installation project entailed transportation and installation of the Angel topside module, weighing about 7 500 tonnes. The CAJV chartered the HLV Black Marlin from Dockwise to carry out the transport and installation of the topside module. The workscope included additional hook-up work for the module to the pre-installed jacket. To be installed by others, the client’s facilities incorporate a 6 500 tonne launched steel jacket with grouted piles and a 5 200 tonne integrated deck tied to three subsea wells.

The installation of the Topside module took place on 1 April 2008.

ACHIEVEMENTS:

- The hook-up scope of work was completed as scheduled

Aquarius Partnership + –

BRIEF FACTS:

Client: Aquarius Platinum South Africa

Projects: Kroondal, Marikana, Blue Ridge and Everest platinum mines

Value: R2,5 billion per annum

Project type: Public private partnership

Duration: 12 years (Terminated in 2012)

Project start: July 1999

Projects: Kroondal, Marikana, Blue Ridge and Everest platinum mines

Value: R2,5 billion per annum

Project type: Public private partnership

Duration: 12 years (Terminated in 2012)

Project start: July 1999

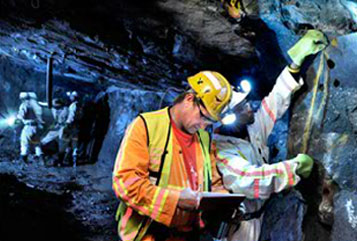

The Kroondal and Marikana platinum mines are located 120 kilometres northwest of Johannesburg in the Bushveld Igneous Complex in the North West Province. This region is one of the world’s most productive platinum regions. These mines are amongst the most cost effective underground platinum mines globally, with a total workforce of more than 6 200 people.

Murray & Roberts has a history dating back more than 80 years of serving the mining industry and is recognised as a leading mining contracting group worldwide with a presence in Africa, Australasia, Asia and North and South America. In 1999, Cementation Africa entered into a landmark contract with Aquarius Platinum to toll mine the shallow platinum ore body at Kroondal.

Murray & Roberts Cementation provides most of the services required to undertake mining activities and carries a shared responsibility for day-to-day operation of the mine, limited to underground activities from initial production planning and mineral resources management (including survey and grade control) to the final delivery of ore to the surface stockpiles. The Kroondal processing plants are supplied from seven main producing shafts with a production output of about 850 000 tonnes of underground ore per month blended with 60 000 tonnes of opencast ore supplied by others. Mining ore is processed by Aquarius in the metallurgical plants to produce a concentrate which is supplied to Impala Refining Services and RPM in Rustenburg.

The capital intensive small mine concept at Kroondal has revolutionised the South African platinum mining industry and incorporates the use of key contractors, highly mechanised mining operations and the outsourcing of high-cost, high-risk smelting and refining operations.

In July 2012 Aquarius Platinum South Africa decided to convert its business model from contract mining to an owner-operator model and Murray & Roberts Cementation agreed to provide the necessary support to Aquarius Platinum with the take-over of all resources to ensure a smooth transition to the owner-operator model.

ACHIEVEMENTS:

- Productivity levels ranked with best in industry

Bay West Mall + –

Project start: June 2013

Project status: Current

Project status: Current

Murray & Roberts Buildings is the primary contractor for the construction of the R2 billion Bay West Mall in Port Elizabeth which has commenced operations.

The 87 500m2 mall located on the Western side of Port Elizabeth is expected to offer significant economic benefits to the region. It is a joint development between the Billion Group and Abacus Asset Management.The project is expected to create about 10 000 direct and indirect jobs during construction and an estimated 1500 permanent jobs will be created to staff 250 retail outlets after the mall opens early in 2015.

Bloukrans Bridge + –

BRIEF FACTS:

Client: NTC

Location: Garden Route, Eastern Cape, South Africa

Value: R11 million

Partner: Concor

Completion: 1983

Client: NTC

Location: Garden Route, Eastern Cape, South Africa

Value: R11 million

Partner: Concor

Completion: 1983

OVERVIEW:

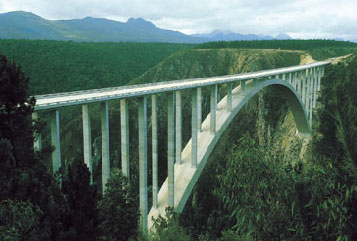

The Bloukrans bridge was one of three Garden Route bridges constructed by a consortium of Murray & Roberts and Concor for the NTC for R25 million.

This proved one of the most demanding and technically complex contracts Murray & Roberts had ever worked on - from a design as well as construction point of view. A tremendous amount of work went into the design of the temporary stage structure which was more complex than the permanent stage.

Bloukrans was constructed by the free suspended cantilever system. That is, every fourth segment - each averaging 5.25 metres in length - is tied back by the BBR suspension cables. This is the first time that the BBR system of prestressing was used for this application

At the time of construction, the Bloukrans Bridge was the largest concrete arch bridge in Africa and the fourth largest in the world. The arch alone, has a mass of nearly 12 000 tonnes!

The Bloukrans Bridge was opened on Friday, 10 June 1983, by the Minister of Transport, after being completed five months ahead of schedule by Murray & Roberts and its partner at the time - Concor.

ACHIEVEMENTS:

- The 451m deck at Bloukrans was completed on February 12, three years since the contract was officially started and an incredible 26 weeks ahead of the original schedule

- The Bloukrans bridge received both the Fulton Award for Excellence in the use of concrete and the SAICE Eastern Cape Branch Award in 1983

Burj al Arab + –

BRIEF FACTS:

Client: HH Sheikh Mohammed Bin Rashid Al Maktoum

Location: Dubai – United Arab Emirates

Partner: Al Habtoor

Completion: 1999

Client: HH Sheikh Mohammed Bin Rashid Al Maktoum

Location: Dubai – United Arab Emirates

Partner: Al Habtoor

Completion: 1999

Completed through the partnership of Murray & Roberts and Al Habtoor for the Ruler of Dubai, Sheikh Mohammed Bin Rashid Al Maktoum, Burj al Arab is the world’s tallest structure with a membrane façade. It was designed to resemble a sailing dhow and built on a man-made island in the Arabian Gulf and it is the ultimate expression of luxury and hospitality.

This project presented a range of construction challenges, not least of which was the logistics of erecting a massive, complex steel structure requiring 9 000 tonnes of steel produced in and transported from South Africa and lifted by three massive cranes. The atrium is 180 metres high, one of the tallest in the world. A 24 metre wide helipad projects from the building 210 meters above the ground.

Partnership and teamwork were key elements of the success. The partnership with Al Habtoor was mutually beneficial, enabling Al Habtoor to tackle this major project in its own market and Murray & Roberts to generate new international growth and success.

The Burj al Arab was officially opened in November 1999, one month ahead of schedule and in time for the turn of the millennia. The project today represents a global icon of construction achievement.

ACHIEVEMENTS:

- Burj al Arab is the world’s tallest structure with a membrane façade

- The atrium is 180 metres high, one of the tallest in the world

- Burj Al Arab was at the time of completion the first 7-star hotel in the world

Cape Town Stadium + –

BRIEF FACTS:

Location: Cape Town, South Africa

Client: City of Cape Town

Partner: 50% WBHO

Project type: Construction

Value: R3,6 billion

Duration: 32 months

Project start: March 2007

Project completed: December 2009

Location: Cape Town, South Africa

Client: City of Cape Town

Partner: 50% WBHO

Project type: Construction

Value: R3,6 billion

Duration: 32 months

Project start: March 2007

Project completed: December 2009

OVERVIEW:

South Africa is the first African nation to host the prestigious FIFA World Cup. New stadiums were built in Cape Town, Durban, Port Elizabeth, Polokwane and Nelspruit in preparation for the 2010 event, and other stadiums around the country were renovated to meet FIFA requirements.

The new Green Point Stadium, also known as Cape Town Stadium, was handed over to the City of Cape Town ahead of schedule on 21 December 2009. The stadium successfully hosted nine World Cup matches, including a semi-final, and will have a positive impact on communities and economic growth in the Western Cape Province for years to come.

The 68 000 seat stadium is located on Green Point Common close to the V&A Waterfront and Cape Town city centre. The stadium is 55 metres high with a fabric façade and a steel cable tensioned glazed roof.

This world class venue has been designed not only to offer football fans an unforgettable experience, but also with a view towards giving the people of Cape Town a versatile venue for decades.

A review team appointed by the Department of Environmental Affairs and Tourism has found that the Cape Town Stadium meets high standards of environmental protection. Water and energy efficiency measures are part of the design and, when the old Cape Town Stadium was demolished to make way for the new one, 95% of the components were recycled and reused. Water from the stadium roof and drainage from the pitch is pumped into ponds on Green Point Common, thus reducing dependency on potable water.

ACHIEVEMENTS:

- The project was handed over to the client in December 2009, two months ahead of the original contract program

- 2,7 million lost time injury free hours were recorded to July 2009

- 1 200 trade employees were trained, graded and developed (The peak construction labour force comprised 2 300 employees)

- The project invested in community based social initiatives, including support for abused women and disadvantaged children

- More than 80 000 school learners attended construction presentations at the Visitor’s Centre

Carlton Centre+ –

BRIEF FACTS:

Location: Johannesburg, South Africa

Contract Value: R38.84 million

Main Contractor: Roberts Construction

Completion: 1972

Location: Johannesburg, South Africa

Contract Value: R38.84 million

Main Contractor: Roberts Construction

Completion: 1972

OVERVIEW:

Built during the late 1960s in the land of gold, the Carlton Centre represented sheer size at its finest.

As a result of marrying four city blocks by closing the intervening streets and making one superblock the Carlton Centre was presented with a chance of doing something different and to a better scale. The Centre had in fact five aspects to it: a 223 metre high office tower, a hotel, a shopping centre, an exhibition hall and a large car park. Representing more than 1 million square feet of construction with each floor half an acre in extent, the Carlton office tower was by far the largest building on the African continent. It had a working population of over 6 000 and lifts that operated at double the speed of any existing in South Africa at the time.

The sheer size of each floor meant a breakthrough in the concept of office layouts in South Africa, and involved the introduction of "deep space" office layout planning, for the first time in the country on a major scale.

The Carlton Hotel, at 603 bedrooms, was the largest in the Southern Hemisphere. More important than size, were the public facilities available which incorporated the highest standards in design, comfort and service.

The difference between the shopping centre and anything else that existed in South Africa at the time is was very dramatic. Wide pedestrian malls connected the various open courts which were completely free of traffic. The entire area was fully air-conditioned and each level provided seven acres of shopping.

The car park accommodated 2 000 cars, most of these housed on four parking levels beneath the shopping and service levels.

ACHIEVEMENTS:

- The centre had the largest city parking arcade in South Africa

- Carlton Centre was the tallest building in the southern hemisphere when completed as well as the tallest building in Africa

Coal Line and Ore Line+ –

BRIEF FACTS:

Company: The UCW Partnership

Client: Transnet Freight Rail

Partners: Toshiba and Mitsui

Project type: Rolling stock infrastructure

Value: R2,1 billion

Duration: Four years

Project start: September 2006

Company: The UCW Partnership

Client: Transnet Freight Rail

Partners: Toshiba and Mitsui

Project type: Rolling stock infrastructure

Value: R2,1 billion

Duration: Four years

Project start: September 2006

OVERVIEW:

COAL LINE

The Richards Bay Coal Terminal (RBCT) is the second largest coal export facility in the world and is expanding its capacity to accommodate increased coal exports. The Coal Line railway system between eMalahleni (Witbank) and Richards Bay plays an important role in the successful operation of RBCT. The Coal Line upgrade project is part of Transnet’s Main Line Locomotive Investment Program that seeks to optimise the operation of the railway system in support of the expansion of RBCT.

Murray & Roberts subsidiary, Union Carriage and Wagon, through The UCW Partnership (UCWP) and with Mitsui African Railway Solutions and Toshiba as its partners, is contracted to supply new locomotives for the Coal Line corridor. Through this project, Transnet will acquire 110 class 19E dual voltage electric locomotives. UCWP is responsible for the overall mechanical design, systems integration, fabrication and assembly of the locomotives. Toshiba contributes to the design, development and supply of the electrical propulsion equipment. The first 12 locomotives have successfully completed the mandatory tests and have been in revenue earning operation since the first half of 2010.

ORE LINE

A dramatic increase in demand for South African iron ore in recent years compelled Transnet to expand its locomotive fleet to facilitate higher volumes of iron ore exports.

In 2007, Transnet awarded UCWP, with its partners Mitsui and Toshiba, the project to supply 44 new class 15E 50 kV electric locomotives for the iron ore rail link from Sishen to Saldanha. This is the most energy efficient locomotive that Transnet has ever added into its fleet. At 30 June 2010, 10 locomotives had been delivered. The first consignment of three locomotives have successfully completed the mandatory tests and have been in revenue earning operation since the second quarter of 2010.

ACHIEVEMENTS:

- 800 new job opportunities secured

- First major new electric locomotive contracts in South Africa since 1994

- The program positions UCWP as a supplier of choice for future rolling stock opportunities

- Class 15E the most energy efficient locomotive ever delivered to Transnet

- At 30 June 2010, 35 new locomotives had been delivered to Transnet by the two projects

Diavik Diamond Mine + –

BRIEF FACTS:

Location: Northwest Territories at Lac de Gras, Canada

Client: Rio Tinto

Partners: Kitikmeot Cementation Mining & Development Ltd

Project type: Mine Development

Start date: 2005

Location: Northwest Territories at Lac de Gras, Canada

Client: Rio Tinto

Partners: Kitikmeot Cementation Mining & Development Ltd

Project type: Mine Development

Start date: 2005

The Diavik Diamond Mine, operated by Diavik Diamond Mines Inc. and owned by Rio Tinto and Harry Winston Diamond Corporation, is located in the Northwest Territories at Lac de Gras. The mine moved from open pit mining methods to underground mining in 2010.

Cementation was selected to carry out underground decline and drift development, as well as extract bulk samples. Construction commenced on site in 2005 with the excavation of two portals and liner installations. Arctic experience and excellent safety performance were key considerations in Cementation being selected to carry out the work.

To carry out the project, Cementation assigned the contract to Kitikmeot Cementation Mining & Development Ltd., a partnership between Kitikmeot Corporation of Nunavut and Cementation. Cementation is the managing partner for the project.

ACHIEVEMENTS:

- The development of skills and training opportunities for Aboriginal and Northern people in the areas of underground mining and safety

Dubai International Airport + –

BRIEF FACTS:

Location: Dubai, United Arab Emirates

Client: Government of Dubai/Department of Civil Aviation

Partners: Al Habtoor Engineering and Takenaka

Project type: Airport construction

Value: AED5,5 billion (R11 billion)

Duration: 36 months

Completion: December 2007

Location: Dubai, United Arab Emirates

Client: Government of Dubai/Department of Civil Aviation

Partners: Al Habtoor Engineering and Takenaka

Project type: Airport construction

Value: AED5,5 billion (R11 billion)

Duration: 36 months

Completion: December 2007

OVERVIEW:

Dubai has become a significant business and logistics hub in the Middle East and is increasingly an attractive holiday destination. This brings millions of visitors to and through the Emirate. Dubai International Airport is more than an important landmark in Dubai; it provides guests and travellers in transit a world class welcome and a taste of what Dubai has to offer.

Murray & Roberts has been established in the Middle East for over 15 years and is a major contributor to growth in the region, having participated in the construction of some of the region’s most prestigious projects such as Burj Al Arab and the ongoing expansion of Dubai International Airport.

The contract for the fit-out, finishes and MEP of Terminal 3, Concourse 2 and the Car Park was awarded in December 2004 to Murray & Roberts and local partner Al Habtoor Engineering, together with Takenaka of Japan. More than 20 000 workers were on site during peak construction, creating a significant logistic and safety challenge to the project team.

ACHIEVEMENTS:

- Phase 1 completion of the project was achieved on schedule at the end of December 2007, meeting accelerated schedule obligations

- This exemplary delivery performance was accompanied by world class safety achievements. A total of 136 million man hours were worked on the project at a cumulative lost time injury frequency rate of 0.17

- At one stage the project accumulated a record 32 million man hours without a lost time accident

Gautrain Rapid Rail Link + –

BRIEF FACTS:

Location: Gauteng, South Africa

Client: Gauteng Provincial Government acting through the Gautrain Management Agency

Partners: 25% Strategic Partners Group, 17% Bombardier, 17% Bouygues

Project type: Public private partnership

Value: R25 billion plus claims and variations

Duration: 54 months and 15 year operational concession

Project start: September 2006

Location: Gauteng, South Africa

Client: Gauteng Provincial Government acting through the Gautrain Management Agency

Partners: 25% Strategic Partners Group, 17% Bombardier, 17% Bouygues

Project type: Public private partnership

Value: R25 billion plus claims and variations

Duration: 54 months and 15 year operational concession

Project start: September 2006

OVERVIEW:

The Gautrain Rapid Rail Link is one of the largest public private partnerships in the world and offers a world class and cost effective, efficient, environmentally friendly and safe solution to commuter and transport challenges in the rapidly developing Gauteng Province. The project also seeks to provide partial relief to the challenge of road congestion by introducing an alternative mode of transport for commuters. It supports economic growth in the province and is creating as many as 7 000 employment opportunities during the construction and commissioning phase.

The project comprises five anchor stations in Johannesburg, Sandton, Pretoria and at OR Tambo International Airport. Additional stations along the route include Rosebank, Marlboro, Midrand, Centurion and Rhodesfield. There is a commuter link between Pretoria, Johannesburg and Kempton Park and an airport express between OR Tambo and Sandton.

The 20 year concession to design, build, part-finance, operate and maintain the 80 kilometre transport system is held by Bombela Concession Company (BCC). Murray & Roberts is a 25% shareholder in both BCC and turnkey contractor Bombela TKC. Murray & Roberts is a 45% shareholder in the Bombela Civils Joint Venture and a 24% shareholder in Bombela Operating Company.

The first phase of the operation, from OR Tambo International Airport to Sandton, was opened 19 days ahead of schedule and 3 days before the Soccer World Cup on 8 June 2010. The second phase, linking Rosebank Station in Johannesburg to Hatfield Station in Tshwane was opened for commercial service on 2 August 2011.

Approximately 3 million passenger trips were accumulated during the first 13 months of operation.

ACHIEVEMENTS:

- Operation of phase 1 commenced 19 days ahead of schedule and 3 days before the 2010 FIFA World Cup

- Approximately 400 000 passenger trips were recorded on Gautrain trains and buses in the first month of operation

- At end July 2010, approximately 65 million man hours had been achieved on the infrastructure portion of the project

Gorgon LNG Project + –

Project start: June 2013

Project status: Current

Project status: Current

OVERVIEW:

The Greater Gorgon gas fields, off Western Australia’s Pilbara Coast, contain more than 40 trillion cubic feet (Tcf) of gas, representing some 25% of Australia’s total known gas resources. The Gorgon project is the largest resource project in Australia’s history and will be adding 15 million tonnes of LNG a year to Australia’s current annual output of approximately 20 million tonnes in a phased manner between 2014 and 2015.

Clough is a key member of the Kellogg Joint Venture – Gorgon (KJV-G), which has been awarded by Chevron Australia the engineering, procurement and construction management (EPCM) contract for all downstream facilities on the project.

The onshore facilities will consist of three five million tonne per annum LNG trains, gas processing and treatment facilities, product storage and offloading, complete offsites, utilities and accommodations. The EPCM contract also includes a 300TJ/d domestic gas plant. The design of the facility features improvements in greenhouse gas emissions performance, including improved waste heat recovery and the injection of reservoir carbon dioxide into the subsurface.

The EPCM effort is planned as a fully modular construction strategy to minimise impact on the island during the construction phase, and is being conducted from two main operating centres located in Perth, Australia and London, UK with support from global centres in USA, Singapore, Indonesia and Japan. Global procurement and numerous international fabrication yards will be utilised to supply the key components of the project and KJV-G personnel will manage these global sites, including the critical supply chain management and logistics processes.

Early construction activity is well underway to ensure that the proper infrastructure and marine logistics capability is established. A work force in excess of 3 500 personnel will construct and commission the facilities over a three year period. It is anticipated that over 40% of the project expenditure will occur in Australia.

Murray & Roberts Marine was awarded the joint venture subcontract to design and construct the material offloading facility for the Gorgon Project. The work has been completed.

ACHIEVEMENTS:

- Five million man hours completed without a days away from work (DAFW) incident

- Major contract and procurement commitments valued at about US$14 billion were secured to 30 June 2010

- Quarantine compliance plan implemented on Barrow Island rated world class by Western Australian Government Environmental Protection Agency in 2009 EPA decision document

Jeffreys Bay Wind Farm+ –

Project start: July 2013

Project status: Current

Project status: Current

Murray & Roberts Construction, in joint venture with Consolidated Power Projects, has been awarded the civil and electrical works, including construction of a new sub-station for the new 138MW Jeffreys Bay wind farm.This is the second largest wind project to have been awarded in the first round of South Africa's Independent Power Producer Programme (REIPPP). It is located between Jeffreys Bay and Humansdorp in the Kouga local municipality and will involve the deployment of 60 Siemens SWT 2,3 MW wind turbines, each with a rotor diameter of 101 metres.The Jeffreys Bay wind farm is expected to generate 200 jobs during construction and 11 permanent operation and maintenance jobs over the 20-year life of the facility.

Medupi and Kusile + –

BRIEF FACTS:

Location: Lephalale, Limpopo Province and eMalahleni, Mpumalanga Province, South Africa

Client: Eskom Holdings Limited

Partners: Mechanical – Hitachi Power Africa, Civil construction – Grinaker LTA (33%)

Project type: Power generation – mechanical, electrical and civil construction

Value: R18 billion (Medupi and Kusile), R4,5 billion (Medupi civil construction)

Project start: November 2007

Location: Lephalale, Limpopo Province and eMalahleni, Mpumalanga Province, South Africa

Client: Eskom Holdings Limited

Partners: Mechanical – Hitachi Power Africa, Civil construction – Grinaker LTA (33%)

Project type: Power generation – mechanical, electrical and civil construction

Value: R18 billion (Medupi and Kusile), R4,5 billion (Medupi civil construction)

Project start: November 2007

OVERVIEW:

Murray & Roberts is playing a pivotal role in the development of South Africa’s new power station infrastructure with its major involvement in the construction of the Medupi and Kusile power stations. These power stations are amongst the largest dry-cooled thermal power stations in the world.

The need for new electricity capacity in South Africa has reached a critical stage and the planned Eskom power generation program will reinstate reliable electricity supply to South Africa and its neighbours over the next 20 years.

A number of Murray & Roberts companies are engaged in this program. Murray & Roberts Projects, in partnership with Hitachi, is responsible for the boiler mechanical portion of the works, comprising 12 units of about 800 megawatt electrical (MWe) each. The Murray & Roberts scope includes structural steel fabrication, erection and mechanical installation works for both power stations. Structural steelwork is being fabricated by Genrec and steel ducting is being fabricated by Energy Fabrication.

Murray & Roberts leads the civil joint venture for the Medupi project where works have progressed well on the first three of the six units. Concor, in joint venture, has been awarded the chimneys and silo contracts for both the Medupi and Kusile projects.

The strategy and investment by the businesses during the early stages of the works to develop South African resources are starting to show great benefit on the projects. The ASGISA trade skills programs and learnerships are progressing well with approximately 720 artisans enrolled. The professional development of engineers is currently a focus area and will remain a priority over the next 18 months.

Both projects have been subjected to significant start-up delay as a result of late access, inadequate site services and design challenges.

ACHIEVEMENTS:

- Medupi boiler 6 civil sectional contractual handover achieved with accelerated program

- Mechanical completion of mainframe and auxiliary bay structural steel for boiler 6

- Fabrication of over 12 000 tonnes structural steel

- Kusile duct workshop established and commissioned

- Over 2,7 million work hours achieved on boiler contract with LTIFR of 0.07; CJV LTIFR 0.87

- Over 14 million man hours worked

Melrose Arch+ –

BRIEF FACTS:

Client: Melrose Arch Development Company - Madevco

Location: Johannesburg, South Africa

Project Start: January 2007

Client: Melrose Arch Development Company - Madevco

Location: Johannesburg, South Africa

Project Start: January 2007

OVERVIEW:

In 2007, Murray & Roberts Construction was awarded contracts valued at over R800 million for hotel, residential and piazza developments at Melrose Arch.

The Melrose Arch precinct is renowned for creating new and cutting edge spaces that fulfil both professional and personal requirements. Melrose Arch is a mixed-use ‘new urbanism’ development that provides retail, commercial and residential space, creating a unique urban experience. The project is located at the northern end of the existing Melrose Arch Development and will benefit from its strategic location, high quality office space, exceptional infrastructure, ample secure parking, safe environment and ease of accessibility.

Murray & Roberts Construction is responsible for the construction of 170 000 square metres of prime office and retail space as well as a basement parkade. The office space consists of 9 highly individualised office buildings. These offices are located within the unique ‘traditional city’ environment that will accommodate retail and leisure opportunities. These together with the adjacent residential areas in the Melrose Arch Development will form a genuinely integrated urban experience.

Murray & Roberts had completed earlier contracts at Melrose Arch in 2001 valued at approximately R188 million.

ACHIEVEMENTS:

- Final Completion was successfully achieved on Phase 1 on 24 November 2009

- Phase 1 Piazza achieved on completion 4 632 333 LTI free hours and a LTIFR of 0.00

- Phase 1 Piazza was awarded the Steel Awards 2009 for tubular structures in conjunction with Omnistruct, Gesteyn & Horak and Pure Consulting

- 2007 GMBA Awards: Achieved 2nd place in the R500m and above category and received the best Safety Officer award

Mossgas FA Jacket: Offshore Oil Platform + –

BRIEF FACTS:

Client: Soekor

Location: Mossel Bay, South Africa

Project Value: R300 million

Client: Soekor

Location: Mossel Bay, South Africa

Project Value: R300 million

OVERVIEW:

The R300-million Mossgas FA jacket made construction history as South Africa's first fixed production platform to be completed onshore.

A subsidiary company, EMSO incorporating Murray & Roberts Engineering Solutions, was awarded contracts by Soekor for initially, the feasibility study and then the conceptual design and project management phases.

The project was officially handed over to Mossgas in 1991, achieving a remarkable number of firsts. This brought to an end a mega-project which started with a feasibility study in January 1985.

A number of Murray & Roberts companies contributed to the overall project including Genrec, Pentow Marine and Murray & Roberts Cape.

ACHIEVEMENTS:

The Mossel Bay offshore project included a series of major achievements in the engineering, fabrication and installation of this facility, namely:

- The longest vertical piles in the world which were fabricated and installed offshore in a single length. The piles were 132 metres long, 82" in diameter, with an average weight of 500 tonnes

- A world record in the Guinness Book of Records for the longest length of 8" pipe laid in a 24 hour period

- At the time of procurement, the longest semisubmersible pumps ever designed and built in the world. The pumps were immersed 72 metres below sea level

- The longest directionally drilled beach crossing under the seabed in the world, measuring 1 kilometre in length. This was repeated three times to cater for the gas, condensate and effluent pipelines

- The world's first integrated drilling derrick and sub-assembly, engineered, transported and lifted into position in one piece

- The first use of an electromagnetic lifting and percussive tool for the installation of the vertical piles. This percussive tool was specially designed to prevent pile stick-up problems where frequency of the wave action was approaching the frequency of the pile

- The first time that an offshore jacket had been launched in such hostile waters, with constant swell and freak wave conditions

- The first offshore project in South Africa. This project was completed on time and to the original parameters established in 1986.

- The first major project that was engineered and fabricated in South Africa with a predominance of South African input.

- The first project where major structural steel nodes were engineered and fabricated in South Africa.

- The biggest steel structure ever built and moved in South Africa. The total weight of the structure was 14 500 t.

- South Africa's first concentrated research into offshore environmental conditions, thus establishing parameters for future reference.

- Special steel produced for the first time in South Africa and now available for sale on world markets.

Multi-Product Fuel Pipeline+ –

BRIEF FACTS:

Location: Johannesburg, South Africa

Company: Hall Longmore

Client: Transnet

Partners: Kulungile Metals Group

Project type: Pipe manufacture

Value: R2,4 billion

Duration: Two years

Project start: August 2008

Location: Johannesburg, South Africa

Company: Hall Longmore

Client: Transnet

Partners: Kulungile Metals Group

Project type: Pipe manufacture

Value: R2,4 billion

Duration: Two years

Project start: August 2008

Murray & Roberts Buildings is the primary contractor for the construction of the R2 billion Bay West Mall in Port Elizabeth which has commenced operations.

OVERVIEW:

To accommodate growth in demand for liquid fuels in Gauteng Province, Transnet allocated R11,2 billion for the construction of a new multi-product fuel pipeline from Durban to Johannesburg to replace and enlarge existing pipeline capacity. The National Multi-Product Pipeline (NMPP) will transport petrol, diesel and jet fuel from the second quarter of 2011. Although the pipeline has also been designed to transport crude oil, the wet commissioning using crude oil will take place at a later stage.

Murray & Roberts operation, Hall Longmore, was awarded the order to manufacture and supply the specialist pipe at a value of R2,4 billion. The order consists of approximately 560 kilometres of Ø610 mm line from Durban harbour to Nigel, and approximately 160 kilometres of Ø406 mm line from Nigel to Langlaagte, and from Watloo in Tshwane to the terminus near Kendal Power Station.

Hall Longmore’s involvement with the NMPP began in 2006 with the submission of capability and feasibility information. Significant technical involvement with the NMPP Alliance Joint Venture culminated in the award of the order for the three layer coated pipe contract to Hall Longmore as part of the Impumelelo Pipeline Joint Venture. Final delivery took place in August 2010.

In preparation for the NMPP project, Murray & Roberts approved a significant capacity expansion at Hall Longmore, including a major upgrade of the electric resistance welded (ERW) plant and a new coating facility to a capacity of 250 000 tonnes per annum. The upgraded plant increased the company’s capability to manufacture pipe by the more efficient ERW method. The upgrade to Ø610 mm and downstream improvements enhanced the company’s capacity to take on future projects of this nature. Many positive spin-offs emerged from the NMPP project that minimised wastage and led to more efficient pipe-making.

ACHIEVEMENTS:

- Manufacture of the first Ø610 mm pipe complying with American Petroleum 5L standards in grade X65 steel

- At 30 June 2010, supply of the Ø406 mm line was complete and 513 kilometres (90%) of the Ø610 mm pipeline had been delivered

- The project was completed in August 2010

National Freeway Improvement Projects + –

BRIEF FACTS:

Location: Johannesburg and Cape Town

Client: South African National Roads Agency (SANRAL)

Customer: 15 major South African contractors and joint ventures

Project Type: Manufacture and delivery of asphalt surfacing materials

Value: R867 million

Duration: 20 months

Project Start: October 2008

Client: South African National Roads Agency (SANRAL)

Customer: 15 major South African contractors and joint ventures

Project Type: Manufacture and delivery of asphalt surfacing materials

Value: R867 million

Duration: 20 months

Project Start: October 2008

OVERVIEW:

Through its asset preservation arm, SANRAL, the Department of Transport has recognised that Cape Town and Gauteng generate nearly 40% of the total value of South Africa’s economic activities. As a result, development in housing, offices, retail and industrial properties in the two centres has grown significantly over the past 10 years, resulting in above average traffic growth. Provision of road infrastructure has not kept up with the increased traffic demand, resulting in a road and freeway network that is under capacity.

The Gauteng Freeway Improvement Project (GFIP) has been implemented to upgrade and expand the Gauteng freeway network to significantly reduce traffic congestion and unblock access to economic opportunities and social development projects. The GFIP will inject approximately R29 billion into the South African economy and approximately R13 billion into the provincial gross geographic product, creating nearly 30 000 direct jobs over its lifecycle.

In anticipation of this development, Much Asphalt upgraded its facilities and capacity and, as a consequence, has been contracted to supply about 70% of the asphalt required to complete phase 1 of the GFIP.

Phase 1 is due for completion before the end of 2010. The initiative that crosses the Johannesburg, Ekurhuleni and Tshwane metropolitan boundaries widens freeways to at least four lanes in both directions and in some sections up to six lanes. This phase of the project will upgrade 185 kilometres of the existing freeway network. Furthermore, over the lifespan of the project, a further 376 kilometres of upgraded and newly constructed freeways are planned for implementation. The network will provide an interconnected freeway system of inner and outer ring roads, incorporating the historically-neglected western and southern Gauteng settlements.

The most significant contribution the investment will make to ordinary citizens is the quality of life improvement that an upgraded road infrastructure will deliver.

ACHIEVEMENTS:

- GFIP: 870 000 tonnes of five different specialist surfacing products (R610 million)

- R300, Cape Town: 266 000 tonnes EVA modified asphalt (R162 million)

- N1, Cape Town: 151 000 tonnes specialist surfacing products with recycled asphalt (R95 million)

- All contracts scheduled for substantial completion for 2010 FIFA World Cup delivered on time

Paris Sorbonne University + –

Project start: 2008

Project status: Complete

Project status: Complete

OVERVIEW:

The Al Habtoor – Murray & Roberts Joint Venture was awarded the design and construction of the Paris Sorbonne University in Abu Dhabi.

The project covers more than 93 000 square metres and was completed in two distinct phases.

The academic buildings consist of a central circular plaza with a 25-metre tall domed cupola, complementing the original Paris-Sorbonne University tower. It features two lecture wings, a library, auditorium, an administrative building and a dining hall radiating out from the central plaza area.

The student residence, sports hall and car park structures are constructed on the western side of the plot.

They provide three levels of parking with landscaped terraces, sports and recreational facilities including changing rooms, and five-storey separate male and female accommodation blocks.

Portside+ –

Project start: August 2012

Project status: Current

Project status: Current

The Portside development will house the provincial headquarters for First Rand Bank and provide 25 000 square meters of corporate and retail space for let by Old Mutual Property.

The 34 storey building will be Cape Town’s tallest and greenest building and will encompass an entire city block of approximately 6 642 square metres, bounded by Bree and Mechau Streets, Buitengracht and Hans Strydom Avenue.

The construction team is working to a fast-track programme and responded to this challenge with innovative solutions such as creating a concrete batching plant on a vacant plot opposite the main construction site allowing them to pump concrete using a boom rather than bringing in ready-mix concrete by truck.

Portside will capitalise on views of Table Mountain and the bay with the tower sitting atop of a parking podium for 1 450 cars.

The building will achieve a minimum 4 Green Star SA rating and the team has adopted green building principles and standards throughout the design and construction phases.

Sun City Entertainment Complex + –

BRIEF FACTS:

Client: Sun International

Location: North West Province, South Africa

Project Value: R25 million

Completion: August 1981

Client: Sun International

Location: North West Province, South Africa

Project Value: R25 million

Completion: August 1981

OVERVIEW:

The Sun City Entertainment Centre project in Bophuthatswana was a remarkable achievement of constructing a R25-million project in less than eight months.

The contract also involved the co-ordination of approximately 60 subcontractors. The contract comprised all the work from plastering and plumbing to joinery and final finishing. It is this part of the contract which makes the Entertainment Centre the most glamorous in the country.

Finishes included mirrored ceilings, special lighting and sound effects, futuristic chromium plated tubes with everything covered in steel and wall paper making it Southern Sun's space odyssey of the 20th century.

Features of the complex included: a 9915 square metre floor area comprising three restaurants, two cinemas, two theatres and 11 shops. Also included was an arena to seat up to 8 500 people and a convention centre capable of hosting 1 000 people.

At its peak, the labour force comprised 1 500 workers.

ACHIEVEMENTS:

- Murray & Roberts won the 1981 Steel Construction Award for its role as main contractor on the Entertainment Centre

Zayed University+ –

Project Start: November 2008 -

Project status: Complete

Project status: Complete

The Al Habtoor – Murray & Roberts Joint Venture was awarded the contract for the design and construction of the new Zayed University campus in Abu Dhabi.

The project will provide educational facilities for 6 000 students in New Khalifa City, near Abu Dhabi International Airport. The campus will cover approximately 75 hectares and will feature a built-up area of 200 000 square metres.

Zayed University was established in 1998 by the federal government of the United Arab Emirates to educate U.A.E national women. It now educates both male and female students and has campuses in Abu Dhabi and Dubai.

Related Links

Copyright © 2014, Murray & Roberts. All Rights Reserved

Douglas Roberts Centre,

22 Skeen Boulevard,

Bedfordview; 2007,

Republic of South Africa

Tel: +27 11 456 6200

Fax +27 11 455 2222

E-mail: info@murrob.com

22 Skeen Boulevard,

Bedfordview; 2007,

Republic of South Africa

Tel: +27 11 456 6200

Fax +27 11 455 2222

E-mail: info@murrob.com